"WE MAKE WHAT YOU WANT"

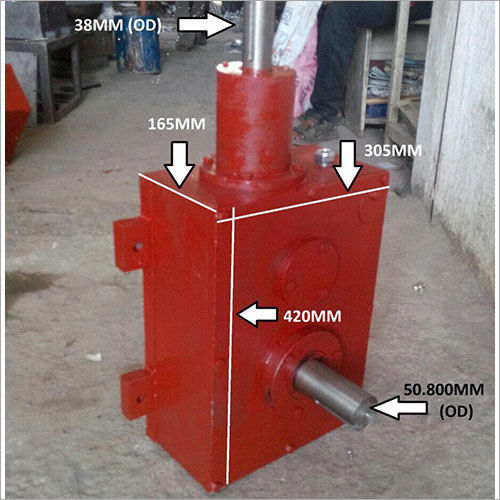

Horizontal Gear box

25000 INR/Piece

Product Details:

- Product Type Horizontal Gear Box

- General Use Industrial gearbox for horizontal applications

- Material Cast Iron / Mild Steel

- Capacity Up to 5000 Nm torque

- Weight (kg) Approx. 120

- Type Helical Gearbox

- Computerized No

- Click to View more

X

Horizontal Gear box Price And Quantity

- 25000 INR/Piece

- 10 Piece

Horizontal Gear box Product Specifications

- No

- Approx. 120

- High efficiency, robust design, easy maintenance

- 150 mm

- 400 mm

- Blue / Grey

- 800 mm x 450 mm x 600 mm

- Up to 20 kW

- No

- Up to 5000 Nm torque

- No

- Industrial gearbox for horizontal applications

- Helical Gearbox

- Cast Iron / Mild Steel

- Horizontal Gear Box

- Low vibration

- 380V/440V

- Mechanical power transmission

- 50 Hz

Horizontal Gear box Trade Information

- 10 Piece Per Month

- 10 Days

Product Description

For our highly appreciated clients, we are regarded as a renowned manufacturer of horizontal gear boxes for cranes. It is carefully engineered utilising the best materials, obtained from our trusted vendors, and advanced machinery at our facility in compliance with the requirements set forth by the industry. The Horizontal Gear Box has a long service life and excels in terms of quality, strength, and performance. It is available from us at incredibly competitive costs on the market.

Reliable Power Transmission for Industrial Use

This horizontal gearbox is crafted for industrial machinery, conveyors, crushers, and mixers, offering dependable mechanical power transmission. Its robust design, conforming to IS standards, ensures long-term serviceability in manufacturing, processing, and heavy-duty applications, making it a preferred choice for Indian industries.

Durable Build and Efficient Performance

Engineered with cast iron or mild steel housing and equipped with heavy-duty bearings, the gearbox operates efficiently even at high speeds (1440 rpm). The oil bath lubrication system, parallel shaft arrangement, and low vibration design extend component life, reduce maintenance needs, and promote quiet operation, benefiting both operators and machinery performance.

FAQs of Horizontal Gear box:

Q: How does the horizontal gearbox ensure reliable power transmission in industrial settings?

A: The gearbox employs precision helical gears, heavy-duty ball or roller bearings, and a sturdy cast iron or mild steel casing to facilitate smooth mechanical power transmission with low vibration and minimal noise, maintaining reliability even under heavy industrial loads.Q: What areas of use are most suitable for this gearbox?

A: This gearbox is ideal for industrial machinery such as conveyors, crushers, mixers, and various horizontal-mounted equipment that require consistent torque, high efficiency, and durability. It serves factories, processing plants, and engineering installations across India.Q: When should routine maintenance be performed on the gearbox?

A: Regular maintenance, focused mainly on oil bath lubrication checks and bearing inspections, should be performed as per the manufacturers schedule or based on the operating hours and load conditions, ensuring optimal performance and preventing wear.Q: Where should the gearbox be installed for maximum efficiency and safety?

A: The gearbox is intended for horizontal foot-mounted installation on stable industrial platforms. Ensure proper alignment with the driven machine and adequate ventilation to maintain the recommended operating temperature range of -10C to +50C.Q: What steps are involved in the lubrication process for this gearbox?

A: Lubrication involves maintaining adequate oil levels in the bath type reservoir, routinely checking for contamination, and replacing the oil as recommended to ensure smooth gear movement, reduce friction, and extend service life.Q: How does the IP55 protection grade benefit the gearbox in industrial environments?

A: The IP55 protection safeguards the gearbox against dust ingress and water jets from any direction, making it suitable for harsh factory surroundings, and enhancing durability and reducing the risk of operational failure.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bricks Machine Parts' category

|

KAILASH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

08045816798

08045816798