"WE MAKE WHAT YOU WANT"

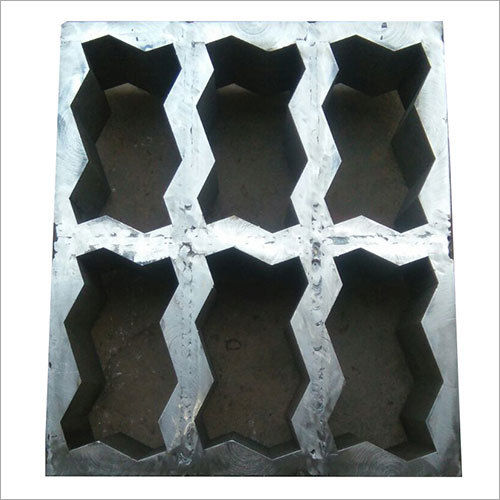

एमएस यूनिपेवर मोल्ड 6 कैविटी

85000 आईएनआर/Set

उत्पाद विवरण:

- सामान्य उपयोग For Paver Block Production

- मटेरियल

- टाइप करें ,

- कम्प्यूटरीकृत

- ऑटोमेटिक

- तरीका हाइड्रॉलिक प्रेशर

- वाइब्रेशन टाइप प्लेटफ़ॉर्म वाइब्रेशन

- अधिक देखने के लिए क्लिक करें

X

एमएस यूनिपेवर मोल्ड 6 कैविटी मूल्य और मात्रा

- 1

- सेट/सेट्स

- सेट/सेट्स

एमएस यूनिपेवर मोल्ड 6 कैविटी उत्पाद की विशेषताएं

- For Paver Block Production

- हाइड्रॉलिक प्रेशर

- Gray

- पीएसआई

- प्लेटफ़ॉर्म वाइब्रेशन

एमएस यूनिपेवर मोल्ड 6 कैविटी व्यापार सूचना

- प्रति महीने

- दिन

- पश्चिमी यूरोप, ऑस्ट्रेलिया, उत्तरी अमेरिका, पूर्वी यूरोप, मिडल ईस्ट, मध्य अमेरिका, दक्षिण अमेरिका, एशिया, अफ्रीका

- ऑल इंडिया

उत्पाद वर्णन

MS Unipaver Mould 6 Cavity is a dimensionally accurate mold that is used for the manufacturing of floor paver blocks with high precision and accuracy It is made up by using advanced machining technologies that make it free from manufacturing flaws Topgrade alloyed materials are used for the fabrication of this component that imparts high tensile and compressive strength to bear extreme impact loads The offered MS Unipaver Mould 6 Cavity can be customized in various sizes as per the clients demandVersatile Mould Design for Paver Blocks

With six cavities, the MS Unipaver Mould maximizes productivity in block making, accommodating both fly ash and clay materials. Its hollow block and brick making capabilities provide manufacturers with the efficiency and adaptability needed for diverse construction projects. The platform vibration system ensures uniform density and finish in each block produced.

Indian Engineering, Global Standards

As a leading exporter and manufacturer based in India, the MS Unipaver Mould 6 Cavity is built to withstand rigorous industrial demands. The hydraulic pressure method (up to 3500 PSI) delivers reliable performance, making it a prime choice for suppliers and service providers seeking consistent block quality and operational durability.

FAQs of MS Unipaver Mould 6 Cavity:

Q: How does the MS Unipaver Mould 6 Cavity operate for paver block production?

A: This machine uses hydraulic pressure, reaching up to 3500 PSI, alongside platform vibration to form strong, uniform paver blocks from fly ash or clay. It is manually operated and does not require computerized or PLC controls, making it straightforward to use.Q: What are the main benefits of using a hollow block and clay brick making machine like this one?

A: The primary advantages include high productivity with its six cavities, versatility in material selection (fly ash or clay), and reliable block strength thanks to hydraulic compression and platform vibration. It suits small to medium-sized manufacturers aiming for consistent output.Q: Where can the MS Unipaver Mould 6 Cavity be used?

A: It is ideal for paver block production facilities, brick manufacturing units, and construction companies. As it is built in India and available through exporters, suppliers, and service providers, it can be sourced for both domestic and international projects.Q: What is the process for making blocks with this machine?

A: Users prepare the raw material (fly ash or clay), load it into the mould, and operate the hydraulic system to press and shape the blocks under high pressure. The platform vibration ensures proper compaction, and the blocks are then removed for curing.Q: When is it suitable to choose this non-automatic block making machine over an automatic one?

A: This machine suits operations that require manageable production volumes, flexibility in process control, and cost-effective block making without the need for automation or computerization. It is especially beneficial for startups and manufacturers in regions where manual systems are preferred.Q: How does the platform vibration feature enhance the block quality?

A: Platform vibration compacts the raw material evenly during moulding, resulting in denser, more durable blocks that meet construction standards. This feature minimizes air gaps and ensures every cavity produces blocks with a smooth finish.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

Bricks Machine Parts अन्य उत्पाद

|

KAILASH ENGINEERING

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

08045816798

08045816798